https://www.navyrecognition.com/index.p ... esign.html

Naval Group Partners with KBR for Australia’s Future Submarine Facility Design

March 2018 Navy Naval Defense Industry News

Posted On Monday, 19 March 2018 09:26

Naval Group has formally signed a Design Services Subcontract (DSSC) with local engineering company, KBR, to assist with the concept design of the proposed Future Submarine (SEA1000) construction yard at the Osborne Naval Shipbuilding precinct in South Australia.

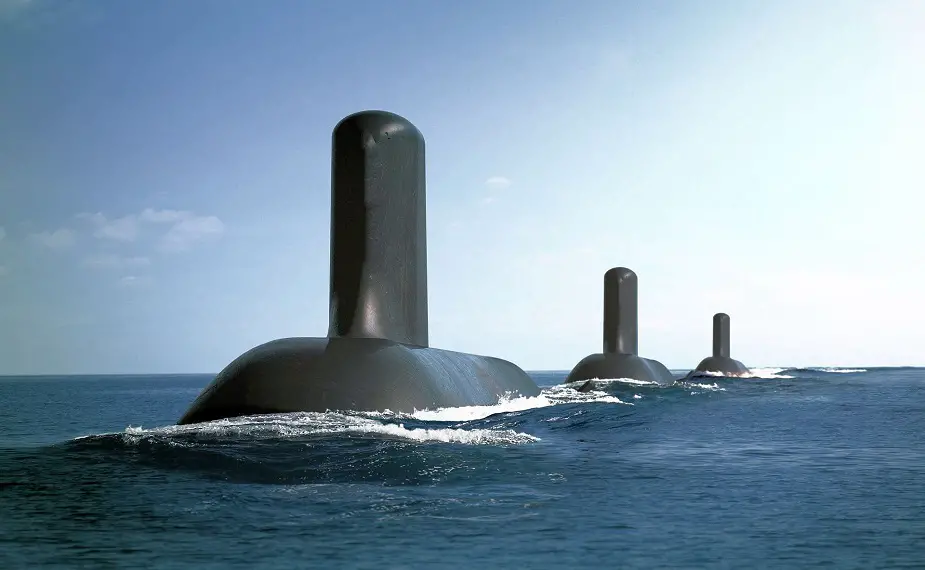

Artist impression: RAN future submarines. Naval Group image.

The submarine construction yard concept design will include the facilities and infrastructure required to construct a fleet of twelve regionally superior Future Submarines for the Royal Australian Navy.

Through the DSSC, KBR will support Naval Group to deliver the concept design for the Future Submarine yard to the Commonwealth of Australia in July 2018.

“We will be utilising Naval Group’s extensive experience building and maintaining nuclear and conventional submarines for the French, Brazilian, Malaysian, Indian and Chilean navies to ensure that the facility is appropriately equipped to build Australia’s Future Submarine fleet” said Brent Clark, Interim CEO, Naval Group Australia.

A team of KBR and Naval Group Australia engineers will undertake design workshops within Australia and France in February 2018 to inform the concept design and facilitate knowledge transfer. The team will draw on Naval Group’s international experience as a reference point for Australia’s Future Submarine yard.

“KBR is excited to be providing our expertise to Naval Group for this nationally significant project that will deliver a world-class future submarine facility, a significant component of the infrastructure enabler of Australia’s Naval Shipbuilding Plan. Having designed the original Collins submarine facility in South Australia in the 1980’s and more recently the Air Warfare Destroyer shipyard, KBR brings extensive local defence infrastructure engineering and program management experience to this important project” said Greg Conlon, KBR President Asia Pacific.

“We anticipate this contract will employee around 100 South Australians and we look forward to working with Naval Group and the Australian Government to maximise opportunities for local industry,” added Conlon.

Naval Group are committed to the involvement of Australian industry in the Future Submarine Program, recognising that it is of vital importance to the construction and sustainment of the submarine fleet into the future, creating job opportunities across Australia.

Australia's Future Submarine Program:

The Australian Government selected Naval Group (then known as DCNS) as its preferred international partner for the design of 12 Future submarines for the Royal Australian Navy. The announcement was made on April 26 2016 by the Australian Prime Minister the Hon. Malcolm Turnbull, the Minister for Defence, Senator the Hon. Marise Payne, The Minister for Industry, Innovation and Science, the Hon. Christopher Pyne and The Chief of Navy, Vice Admiral Tim Barrett. DCNS was competing with the Shortfin Barracuda design against TKMS' Type 216 and Japan's Soryu class designs. Based on the French Navy Barracuda SSN currently in final stage of construction, Australia's future submarine will be will be 97 meters in length and 8.8 meters in diameter.

In September, Lockheed Martin was selected as the preffered combat system integrator. All 12 submarines are expected to be built in Adelaide (South Australia) with technology transfer from Naval Group.

#Official Defence Thread

Re: #Official Defence Thread

Re: #Official Defence Thread

https://www.asiapacificdefencereporter. ... -ModellingAustralian Engineers from Four Companies to Collaborate on Future Frigate 3D Modelling

Adelaide, 14 March 2018

44 highly-skilled Australian engineers and designers have commenced 3D Digital Model courses to develop electricity, structural and outfitting design activities to develop a naval design capability for complex ships. Designers from South Australian companies ASC and Cornell Design, as well as Victorian firm Invenio, will work alongside Navantia Australia employees as part of the program, which will grow Australian Industrial Capability.

“For the future growth of Australian defence industry, it is vital that we grow digital workforce skills, particularly in design, 3D modelling, and development of the digital twin,” said Navantia Australia’s Managing Director, Donato Martinez. “The training we are undertaking is an important part of the transfer of design technology and tools to Australia as part of building local design capability in our role as design manager of the Hobart Class.”

Navantia Australia will be providing a training program through which trainees will be taught to use the FORAN digital design software. FORAN is a fundamental tool used to create the 3D models and the digital twin, or ship zero, used in design and build phases. Through the use of FORAN, seamlessly integrated into our Business Management System, Navantia Australia is able to reduce costs and improve productivity in the design and construction of vessels.

“The program will provide the skills required for the future workforce to work on complex and highly-skilled naval projects,” said Mr Martinez. “We are proud to be working with local companies to upskill the future workforce and help build a thriving advanced manufacturing industry in Australia centred on continuous naval shipbuilding. This training program is a first for Navantia Australia and will involve both formal and workplace training components, representing a significant investment in developing the workforce capability.”

The training program will run over six months.

Re: #Official Defence Thread

So money was allocated for the shipbuilding college in the budget, and still no word on when it’s all meant to kick off?

Re: #Official Defence Thread

SEA5000 announcement is set for Friday.

Watch this space - will it be cost or capability that wins?

Am figuring that with an announcement as big as this, the PM will be down at the shipyard spruiking jobs for SA

Watch this space - will it be cost or capability that wins?

Am figuring that with an announcement as big as this, the PM will be down at the shipyard spruiking jobs for SA

Sticking feathers up your butt does not make you a chicken

-

I Follow PAFC

- High Rise Poster!

- Posts: 447

- Joined: Tue Jul 08, 2014 7:23 pm

Re: #Official Defence Thread

BAE Systems beats Spanish and Italian designs for $35 billion warship building program.

A British company has been chosen for Australia's largest peace-time warship-building program, under a $35 billion contract to produce nine high-tech, anti-submarine frigates.

BAE Systems beat off fierce competition from rival Spanish and Italian designs and will begin construction in Adelaide in 2020.

More: http://www.abc.net.au/news/2018-06-29/b ... am/9922666

A British company has been chosen for Australia's largest peace-time warship-building program, under a $35 billion contract to produce nine high-tech, anti-submarine frigates.

BAE Systems beat off fierce competition from rival Spanish and Italian designs and will begin construction in Adelaide in 2020.

More: http://www.abc.net.au/news/2018-06-29/b ... am/9922666

I Follow The Port Adelaide Football Club

https://www.facebook.com/IFollowThePAFC/

https://www.facebook.com/IFollowThePAFC/

Re: #Official Defence Thread

Am so glad that capability won.

These will be the most capable ships in the RAN - and extremely effective ASW frigates.

Funny that subs and ASW frigates will be built next to each other - basically designed to destroy each other.

These will be the most capable ships in the RAN - and extremely effective ASW frigates.

Funny that subs and ASW frigates will be built next to each other - basically designed to destroy each other.

Sticking feathers up your butt does not make you a chicken

Re: #Official Defence Thread

Does anyone know the industry plan that BAE have for the Future Frigates program? I remember hearing that Fincantieri were going to establish a facility at Osborne to manufacture thrusters and other marine propulsion equipment that would then be exported to their shipyards in the asian region. I also remember that they were planning on establishing a regional maintenance facility that would do repair & refurbishment work on cruise liners.

Re: #Official Defence Thread

Repair and refurbishment of cruise liners sounds like a pipe dream. I don't think they physically fit as far upriver as the Osborne shipyard. A cruise liner is huge compared to a destroyer or frigate - length, beam, draught. I doubt there is space near the passenger terminal anywhere that could be dredged enough to provide a refurbishment berth, even if it didn't need to be able to be lifted out of the water or dry docked.Spurdo wrote: ↑Sat Jun 30, 2018 9:51 pmDoes anyone know the industry plan that BAE have for the Future Frigates program? I remember hearing that Fincantieri were going to establish a facility at Osborne to manufacture thrusters and other marine propulsion equipment that would then be exported to their shipyards in the asian region. I also remember that they were planning on establishing a regional maintenance facility that would do repair & refurbishment work on cruise liners.

Re: #Official Defence Thread

Most of the cruise ships that come in wouldn't be able to be turned around in the waters where ASC is, they are too long.

Ovation of the Seas for example is nearly 350m in length, longer then the width of water from shore to shore.

Going a bit further off topic(since we are talking about it, but probably belongs in visions) what they should do is widen the channel, dredge it, and build a cruise terminal just to the north of the expressway/rail bridges. Would add extra impetus to move the heavy industry just to the west of that site out of the area, and generally clean up the wider area.

Ovation of the Seas for example is nearly 350m in length, longer then the width of water from shore to shore.

Going a bit further off topic(since we are talking about it, but probably belongs in visions) what they should do is widen the channel, dredge it, and build a cruise terminal just to the north of the expressway/rail bridges. Would add extra impetus to move the heavy industry just to the west of that site out of the area, and generally clean up the wider area.

Re: #Official Defence Thread

With all the talk of Naval Group (DCNS) and the Federal Government seemingly not being able to come to an agreement on the Future Submarines Program, it seems the Japanese have announced if the deal falls through that they would be willing to take over the contact and not only build the future submarines at Osborne, but also use ASC to build submarines for the Japanese Navy. IMHO although there might be a slightly longer wait until commencement of construction, this seems like a much better deal as the Soryu Class submarines that the Japanese were proposing are considered to be among the best if not the best diesel-electric submarines in the world.

I also noticed that on the SCAP/DAC website, there are some basic plans up for the future submarine construction yard. Both plans and the article are below

[Article] - https://thediplomat.com/2018/10/japan-o ... s-through/

[Plans] - https://www.saplanningcommission.sa.gov ... urecon.pdf

I also noticed that on the SCAP/DAC website, there are some basic plans up for the future submarine construction yard. Both plans and the article are below

[Article] - https://thediplomat.com/2018/10/japan-o ... s-through/

[Plans] - https://www.saplanningcommission.sa.gov ... urecon.pdf

Re: #Official Defence Thread

The problem with the Japanese option was that they weren't willing to share all the technologies with our navy. That would hamper our navy's operations and capabilities.

We should have gone and still should go for the American Virginia Class, or an evolved design.

It's interesting that ASC keeps laying experienced workers off, but a few months ago was hiring new apprentices.

We should have gone and still should go for the American Virginia Class, or an evolved design.

It's interesting that ASC keeps laying experienced workers off, but a few months ago was hiring new apprentices.

Re: #Official Defence Thread

That would also mean either building a nuclear supply chain in Australia, or sending our boats to the US to refuel them.rev wrote: ↑Fri Oct 19, 2018 5:46 pmThe problem with the Japanese option was that they weren't willing to share all the technologies with our navy. That would hamper our navy's operations and capabilities.

We should have gone and still should go for the American Virginia Class, or an evolved design.

It's interesting that ASC keeps laying experienced workers off, but a few months ago was hiring new apprentices.

If we truly wanted a local shipbuilding industry we should be looking at designing our own

Re: #Official Defence Thread

The nuclear reactors on subs don't need refueling for a long, long time. They'd probably see the end of their life cycle before needing refueling.Goodsy wrote: ↑Fri Oct 19, 2018 6:37 pmThat would also mean either building a nuclear supply chain in Australia, or sending our boats to the US to refuel them.rev wrote: ↑Fri Oct 19, 2018 5:46 pmThe problem with the Japanese option was that they weren't willing to share all the technologies with our navy. That would hamper our navy's operations and capabilities.

We should have gone and still should go for the American Virginia Class, or an evolved design.

It's interesting that ASC keeps laying experienced workers off, but a few months ago was hiring new apprentices.

If we truly wanted a local shipbuilding industry we should be looking at designing our own

And true, we have an abundance of resources both natural and human in this country, we could be self sufficient in a lot of areas, but our governments signed us up for globalization instead so we aren't.

Personally though I think our best option is to piggy back onto the Americans, our closest and most important ally. They have the biggest budget for r&d in the world, and are decades ahead in many areas especially when it comes to defence/military.

Re: #Official Defence Thread

Some may say the US is well ahead in defence technology and development - but I often wonder how much is propoganda versus reality. My biggest thought about the whole thing is more that I feel submarines and surface ships appear to be totally ready for "disruption" and that lethal, mass manufactured drones will very soon render them redundant....I remember reading a while back about the US already trialling drone mini-subs - and no doubt in a short timeframe there will be networked mini-nuclear drone subs prowling the ocean 24/7 and never needing to surface and armed to the teeth.

Re: #Official Defence Thread

For construction / assembly of the 9 Frigates, the shipyard steelwork is starting to take shape. This first photo shows one of the assembly buildings underway, located next to a far more substantial slab and the beginning of a much taller assembly area. I understand that there will be parking for 5,000 cars so that gives an indication of how much this area will change over the next 2 years and generate jobs

- Attachments

-

- FF 1.JPG (2.84 MiB) Viewed 10593 times

Who is online

Users browsing this forum: No registered users and 0 guests